Business

Finance

manufacturing

Chemicals

Chemical Manufacturing

Rubber Processing

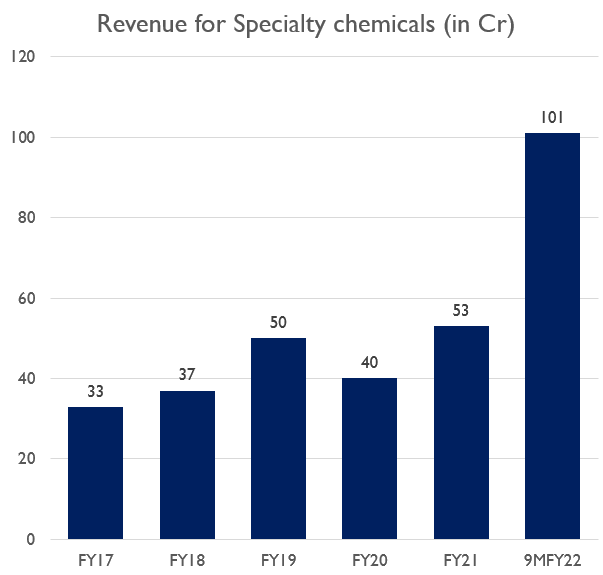

Specialty Chemicals

#YashoIndustries Long Thread 🧵🧵

Like & Retweet for Max reach !

CMP - ₹1865

Introduction

Yasho Industries is a Mumbai-based Specialty chemicals manufacturer which was incorporated in 1985 by Mr. Vinod Jhaveri.

Like & Retweet for Max reach !

CMP - ₹1865

Introduction

Yasho Industries is a Mumbai-based Specialty chemicals manufacturer which was incorporated in 1985 by Mr. Vinod Jhaveri.

The company started operations with aromatic chemicals and specialty chemicals. In 2000, the company started manufacturing rubber chemicals and lubricant additives which are used in rubber processing industries.

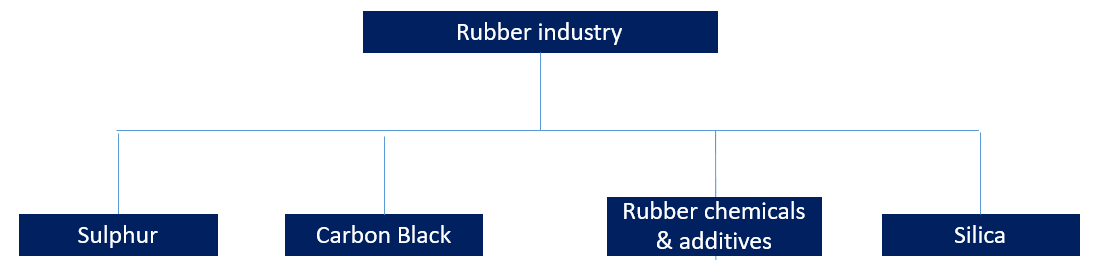

Business Segments

The company has four business verticals with the highest revenue contribution from rubber chemicals. Rubber chemicals, Lubricant additives and specialty chemicals together contribute 59% of total revenues and the rest

The company has four business verticals with the highest revenue contribution from rubber chemicals. Rubber chemicals, Lubricant additives and specialty chemicals together contribute 59% of total revenues and the rest

The aroma chemical industry is such that peers in the industry tend to avoid manufacturing chemicals which are manufactured by others. Thus cross selling and customer retention is higher.

There are a total 35 products in the segment with single digit margin.

There are a total 35 products in the segment with single digit margin.

Due to high dependency on aroma chemicals and increasing competition on antioxidants markets, the company diversified the product portfolio into rubber chemical segment.

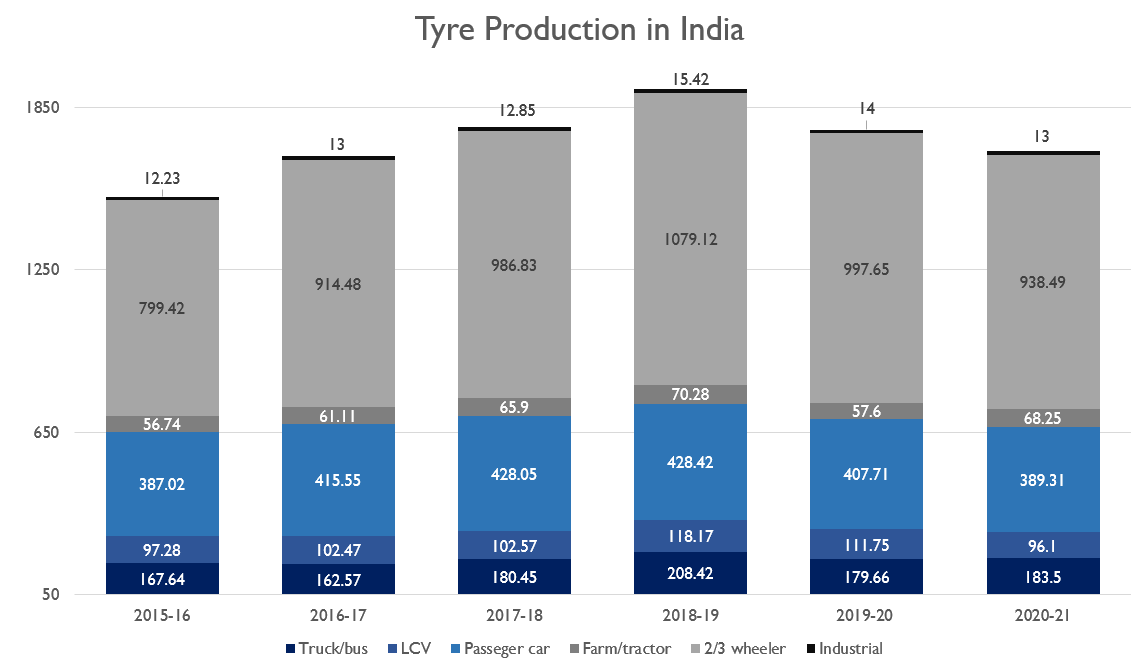

The Tyre industry is the leading consumer of rubber, with over 70% of the global market share.

The Tyre industry is the leading consumer of rubber, with over 70% of the global market share.

Sulphur- Sulphur is a key component in the rubber processing industry. Tyres are made out of vulcanised rubber. The vulcanization process is what makes the tires hard and heat resistant. The vulcanization, or curing process, is based on the reaction of unsaturated rubber

hydrocarbon molecules with sulphur in the presence of zinc oxide and other inorganic bases. A number of early developments have spurred the growth of the rubber industry since the initial discovery of vulcanization by Goodyear in 1844 and the growth and global spread of rubber

plantations.Sulfur remains the most successful and economical cross linking agent even today.

Other chemicals used for cross linking of polymers are Sulphur Monochloride, Tellurium, Selenium, Thiuram accelerators, Polysulphide polymers, p-Quinone Dioxime S, Metallic Oxides,

Other chemicals used for cross linking of polymers are Sulphur Monochloride, Tellurium, Selenium, Thiuram accelerators, Polysulphide polymers, p-Quinone Dioxime S, Metallic Oxides,

Organic Peroxides, Di-isocyanates,etc. (mostly for specialised applications).

Carbon Black: Carbon black is a very pure form of carbon which is added to rubber formulation in powder form. It helps the rubber not erode from friction which is critical for tires that are on the road all day thus acting as a type of reinforcement

inside the rubber of the tire and making it stronger. Some tires may be made up of as much as 30% carbon black.

Silica: When a tire generates less friction, it helps the tire last longer.Silica is added to tires to reduce rolling resistance.

Silica: When a tire generates less friction, it helps the tire last longer.Silica is added to tires to reduce rolling resistance.

It helps increase fuel economy, because less power is needed to push the car when it is met with less resistance

Rubber Chemicals: Not all tires are made entirely from naturally occurring rubber. Synthetic rubber has some advantages over natural rubber, because

Rubber Chemicals: Not all tires are made entirely from naturally occurring rubber. Synthetic rubber has some advantages over natural rubber, because

it is more pure and because it is very cost effective. Unlike natural rubber which is derived from the SAP of rubber trees, synthetic rubber is derived from crude naphtha. It has been reported that some 500 chemically, more or less, well-defined substances are used in the

Swedish rubber industry itself.

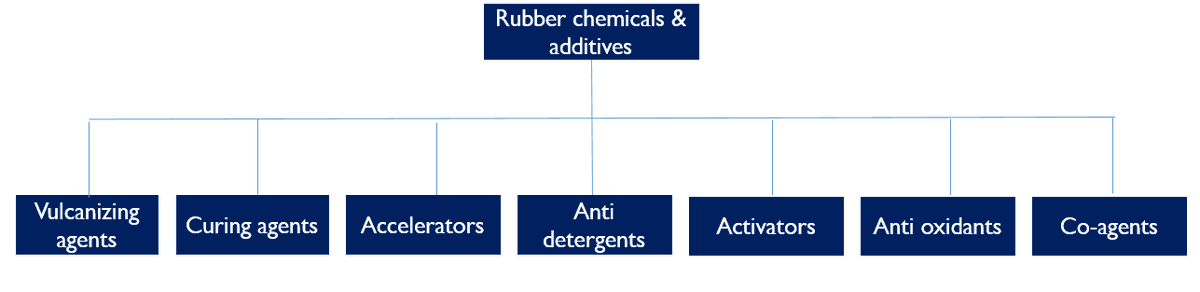

Additives are used by the companies to enhance the process efficiency and product durability. Additives can thus be classified according to their functions which include: Vulcanizing agents,

Additives are used by the companies to enhance the process efficiency and product durability. Additives can thus be classified according to their functions which include: Vulcanizing agents,

The rubber chemicals manufactured by Yasho industries are accelerators, antioxidants and co-agents.

Accelerators: These are critical and essential chemicals which accelerate the sulphur cross linking reaction (vulcanization)

Accelerators: These are critical and essential chemicals which accelerate the sulphur cross linking reaction (vulcanization)

vulcanization plateau and optimum cross link density.The basic accelerators such as Guanidines, Thiurams, and Dithiocarbamates etc are used as Secondary accelerators to activate the primary accelerator.

Over 150 different chemicals belonging to different classes of composition are known to function as accelerators for rubber vulcanization of which around 50 accelerators are most commonly used by the Rubber Industry.

Antioxidants: These are essential chemicals which ensures that the normal or desired life cycle of a rubber product is achieved. All unsaturated polymers are vulnerable to Reactive Environmental Factors such as: Oxygen, Heat, UV light etc which degrade

Rubber chemicals constitute 4% of the rubber consumption.

The Tyre industry is the leading consumer of rubber chemicals. Rubber processing chemicals are being used for making tyres more durable and providing them strength to withstand any harsh environment

The Tyre industry is the leading consumer of rubber chemicals. Rubber processing chemicals are being used for making tyres more durable and providing them strength to withstand any harsh environment

Radial truck and bus tyres segment is directly proportional to infrastructure growth in the country which is also a growth engine for tyre industry.

While the sub segment (agriculture) is largely known as non-cyclical in nature, the other sub

While the sub segment (agriculture) is largely known as non-cyclical in nature, the other sub

There are more than 250 different chemicals which are used in manufacturing of tyres.With chemical industry downfall in China and shutdown of rubber chemical companies is a key driver of opportunities for Yasho industries.

China is currently contributing to 75% of global rubber chemicals supply although their domestic demand does not exceed 35% of the global demand

Lubricants are used to reduce friction and wear, dissipate heat from critical parts of equipment, remove and suspend deposits that may affect performance and protect metal surface damage from degradation and corrosion.

Base oils themselves perform most of the functions of lubricants. But they can only do part of the job. Additives are needed when a lubricant’s base oil doesn’t provide all the properties the application requires.They typically range between

In the last 3-4 years, the company has expanded their capacity from 6,000 MTPA to 11,000 MTPA.

This expansion was primarily to suffice ongoing demand into rubber, lubricant and specialty chemicals segments.

This expansion was primarily to suffice ongoing demand into rubber, lubricant and specialty chemicals segments.

The plant facilities are designed to be a multi-purpose plant, which gives an edge to be flexible with market demand.

Loading suggestions...